Spout Inserting Device - BM|Flex Sagl

Main menu:

- Home Page

- Separatore 3

- What we do

- Separatore 9

- Products

- Separatore 6

- Principals

- Separatore 5

- News & Events

- Separatore 4

- 2nd Hand

- Separatore 8

- Pre-Made Pouches

- Separatore 10

- Contacts

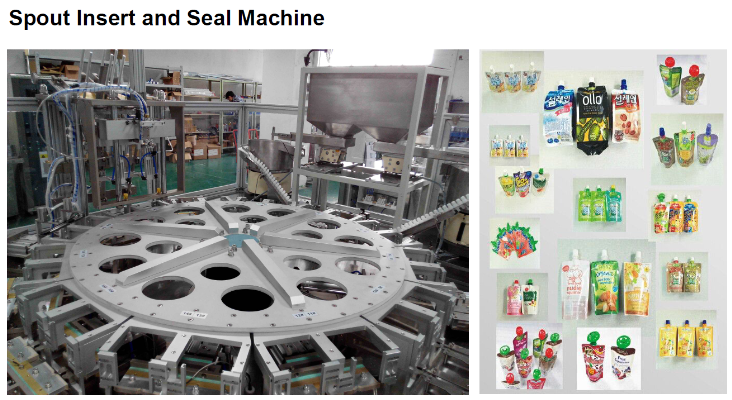

Spout Inserting Device

Products > BM|Flex

This machine is used to insert and weld the spout into packaging pouch, such as stand-up pouch, three side seal pouch.

It's used for center spout (in the middle of pouch side).

Features

- Wholly automatic; one machine needs only one operator (load large quantity of spouts and pouches at one time).

- Turntable design occupies small space and saves room.

- All parts made of aluminum and stainless steel, meets the quality and hygiene requirement of food, pharmaceutical, environmental and health industries.

- Easy to operate, precision control, stable running, can work long time continuously.

- The machine adopt Mitsubishi temperature control module, SMC pneumatic drive unit, and Mitsubishi PLC, which ensures high quality, high performance and long life.

- Automatically detect error, alarm, stop, diagnose, and display the location of malfunction.

Structure

- The machine consists of spout feed system, pouch feed system, heat sealing system, pouch collect system, central control system and base stand.

- Spout feed system consist of hopper bucket, vibration device and guide rail. Photoelectric sensors realize wholly automatic control.

- Pouch feed system use sucking disc to handle pouch. Pouch feed and heat sealing systems have double work stations, double efficiency.

- Heat sealing system include the turntable, heat sealing bars and work stations. There are preheating bar 1 group, heat sealing bar 4 groups, cooling bar 1 group.

- The heat sealing work station frame can be adjusted for different pouch size; and user can customize sealing bar for different spout size or shape.