Bag Making Machines - BM|Flex Sagl

Main menu:

- Home Page

- Separatore 3

- What we do

- Separatore 9

- Products

- Separatore 6

- Principals

- Separatore 5

- News & Events

- Separatore 4

- 2nd Hand

- Separatore 8

- Pre-Made Pouches

- Separatore 10

- Contacts

Bag Making Machines

Products > BM|Flex

T-Shirt bag machine provides an efficient and economical way for the large scale production of shopping bags in high density and low dansity polyethylene. Machine is servo driven and available in twin tracks to process two individual pre-gusseted rolls of film as well as for jumbo rolls complete with slit sealer and post gusseting system. The performance consistency and reliability of this machine enhances the productivity of the converters.

The Bottom Seal Machine was designed to provide a cost effective solution for the production of bottom seal bags using hot wire sealing and flying knife cutting technology.The latest 2013 model, with improved mechanical features, allow machine to run substantially faster with less wear and tear components thus reducing running and maintenance cost even further. Availabme in different widths, machine can be equipped with an array of accessories including a winding system for the production of bottom seal as well as twin seal perforated bags on roll.

The Bottom Seal Machine is designed for the high speed production of bottom seal bags over a wide range of film material and gauge. Equipped with latest state of the art servo technology, machine can run clamped bags at speed of up 200cpm. Sealing jaws are fitted with Nichrome wires and cutting is by a flying knife. Machine can be equipped with a range of accessories such as handle punch, angle sealers, slit sealers and a bag brushing unit for thin gauge application. It is easy to operate, very reliable and requires minimal maintenance.

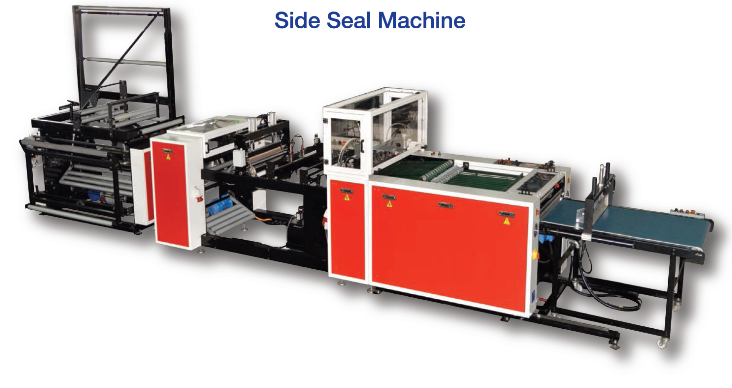

The Side Seal Bags Machine, incorporating a range of differemte accessories, converts a variety of side seal bags in polyethylene and polypropylene from tubular and sheet film. An optional twin seal/bottom seal assembly with servo driven flying knife for cutting, allows the three different types of bag to be converted on this versatile machine.

The Bag on Roll Machine uses a rotary drum sealing system for the continuous production of core less bag on roll in one or two tracks. The longer seal time achieved with drum sealing allows sealing at lower temperatures thus offering greater processing flexibility and product seal quality. Machine is easy to operate, reliable and requires minimal maintenance. It can be equipped with accessories such as "C" folder, V-board, slit sealers, post gusseter for the production of different bag type.

The Wicket Bag Machine features a multiple servo machine for the production of plain and printed wicket bags for the automatic packaging industry. Available in different machine widths and with a range of accessories, machine can produce a range of products including bread bags, zipper bags and diaper bags. Also available in twin wickets for saddle bags.